Dear Valued Customers and Suppliers,

It is our distinct honor to announce the merging of two proud, family-owned and operated companies: International Chemical Company (ICC) and H&B Petroleum. ICC, a fourth-generation chemical company founded in 1906, recently purchased the assets of H&B Petroleum, a manufacturer and packager of metalworking fluids and lubricants since 1919.

We couldn’t be more proud at the prospect of endeavoring to strengthen the legacy which H&B Petroleum has strived for so long to cultivate; one of high quality and outstanding customer service.

Please click here for more information about International Chemical Company.

Please use sales@e-icc.com/ 888-CALL-ICC for all order submissions, technical support, and general correspondence.

The HABCOOL™ Story

STUART HUBER

founder of H&B Petroleum

Welcome to H&B Petroleum Company!

Stuart Huber founded H&B Petroleum Company in 1919 in Paterson, New Jersey. At the time, Paterson was home to Cook Locomotive Works, the Colt Firearms Company, and many factories producing silk fabrics. H&B was proud to supply lubricants for the machinery and steam engines that powered these early manufacturing enterprises.

The depression years proved to be difficult for H&B, but as World War II approached, the company developed premium metal-cutting oils, which were embraced by the metalworking industry and were used to assist in manufacturing the arsenal of democracy that would go on to win the war.

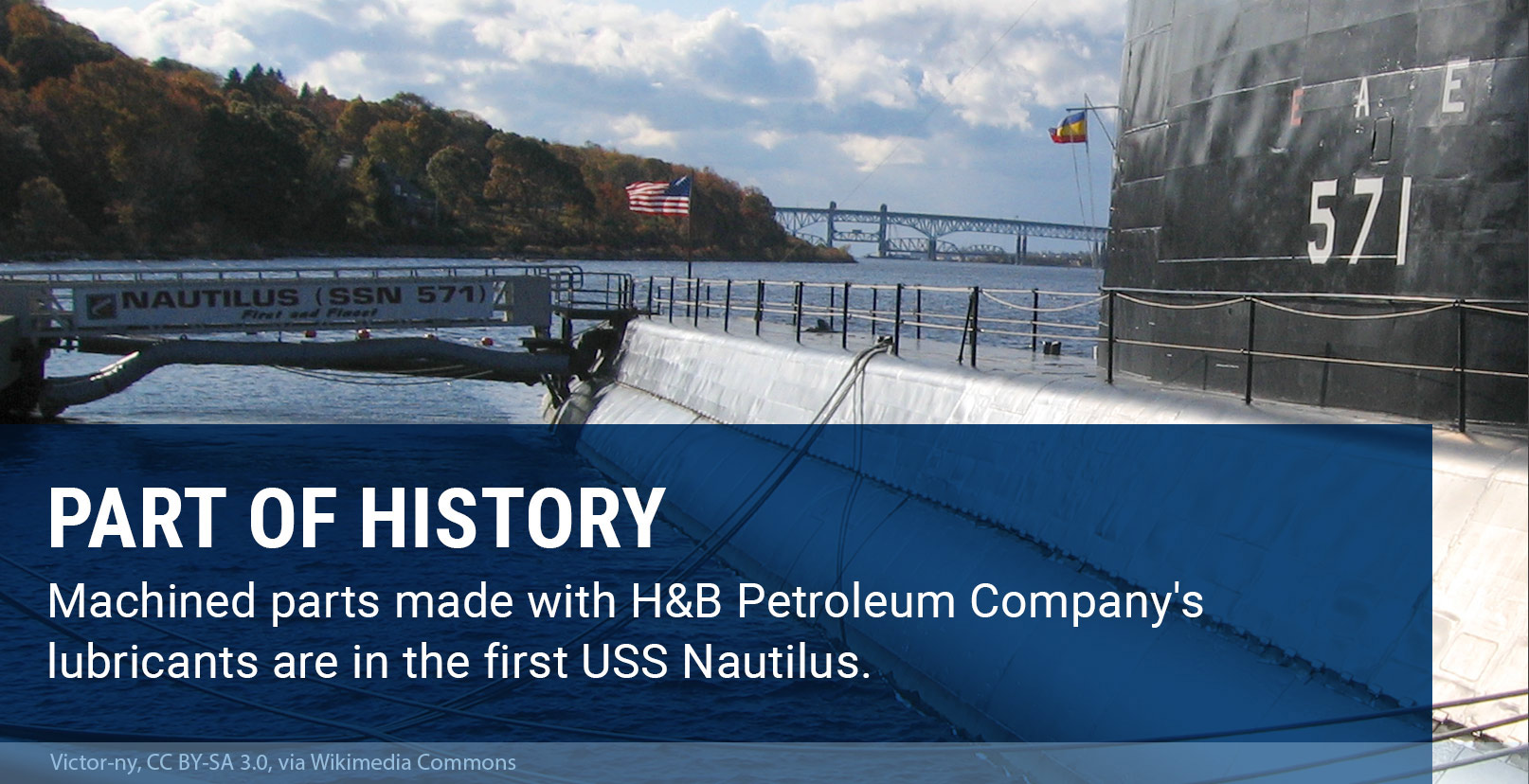

The post-war years brought with them the growing use of new high-performance metal alloys, which opened new opportunities to research and develop cutting-edge cutting oils. One of these high-performance premium oils was HABCOOL 318 Super Tapping and cutting oil, which has been an H&B staple and best-seller ever since. In just one example from its storied history, HABCOOL 318 was supplied to Electric Boat Company, which used it to machine parts that ultimately made it aboard the world’s first nuclear submarine: “Nautilus.”

Stuart Huber passed away in 1968 and was succeeded as president by his son, Stuart D. Huber. In 2022, and after more than 100 years of continual operation and family ownership, H&B Petroleum agreed to be purchased by International Chemical Company, itself a family-owned manufacturer of premium metalworking chemistry, who in turn agreed to continue fostering the legacy of the Huber family by manufacturing HABCOOL products to the highest standards, and providing the outstanding customer service for which H&B Petroleum is known.

We are happy to assist you with any questions you may have about our complete line of metalworking fluids, or discuss your specific metalworking operations to find improvements and solutions.

We can be reached via e-mail at info@e-icc.com and sales@e-icc.com, or via telephone at 888-CALL-ICC.

HABCOOL 318 Usage Instructions

HABCOOL 318 PACKAGING

HABCOOL 318 is normally used as it is received (straight), and is applied with a brush or a pour-spout can directly to the tap or chaser.

Exceptional cutting oil for use in bar machines and chuckers can be easily and inexpensively made by adding HABCOOL 318 to a light mineral oil in a proportion suitable to the toughness of the metal being machined.

For example, many manufacturers formulate their own cutting oils using mineral oil of 150-200 SUS viscosity blended with HABCOOL 318, resulting in thinner metal-cutting oil when the situation calls for it.

If machining metal using turret lathes, automatic tappers, screw machines, chuckers, etc., HABCOOL 318 is recommended to be blended at 25% to 50% by volume depending upon the machinability of the material and the severity of the machining operations.

A proper combination of HABCOOL tapping oil and mineral oil will reduce heat and friction and allow for an increase in cutting speeds and feeds.

Readily Available for Immediate Shipping and Delivery!

HABCOOL 318 is available from International Chemical Company and leading distributors in the U.S. and Canada.

HABCOOL 318 is packaged in 1-gallon containers, 5-gallon pails, and 55-gallon drums.

HABCOOL 318 Samples

Call now to receive a free sample of HABCOOL 318 SUPER TAPPING OIL!

Try HABCOOL 318 on your toughest machining operations, and report back if you don't observe an increase in speeds and feeds. For especially challenging applications, we have experienced technical representatives standing by to offer support and provide operational recommendations.

Call us at 888-CALL-ICC, Monday through Friday, 8:00 a.m. to 4:00 p.m., Eastern Time.

Thank you for visiting! We look forward to working with you!